AMR- AUTONOMOUS MOBILE ROBOT

AMR Intelligent robot chassis,

all-round indoor autonomous navigation, smart Factory & Warehouse Solution

Auto Run and Stop

Auto Detect obstacles

Auto Turn Around

Auto Charge Battery

SYMKOS

AMR - AUTONOMOUS MOBILE ROBOT

Perform various job by finding a suitable route with recognizing nearby objects automatically. No guide tape and rail when running.

- SYMKOS unique Autonomous robot dispatch system

- High efficient and accurate automatic delivery

- Automatic planning of the optimal route

+ Running route setting: Easy setting by mapping file or on the touch screen

+ Sensing obstacles by LIDAR sensor

+ Barcode reading & recognition of job area

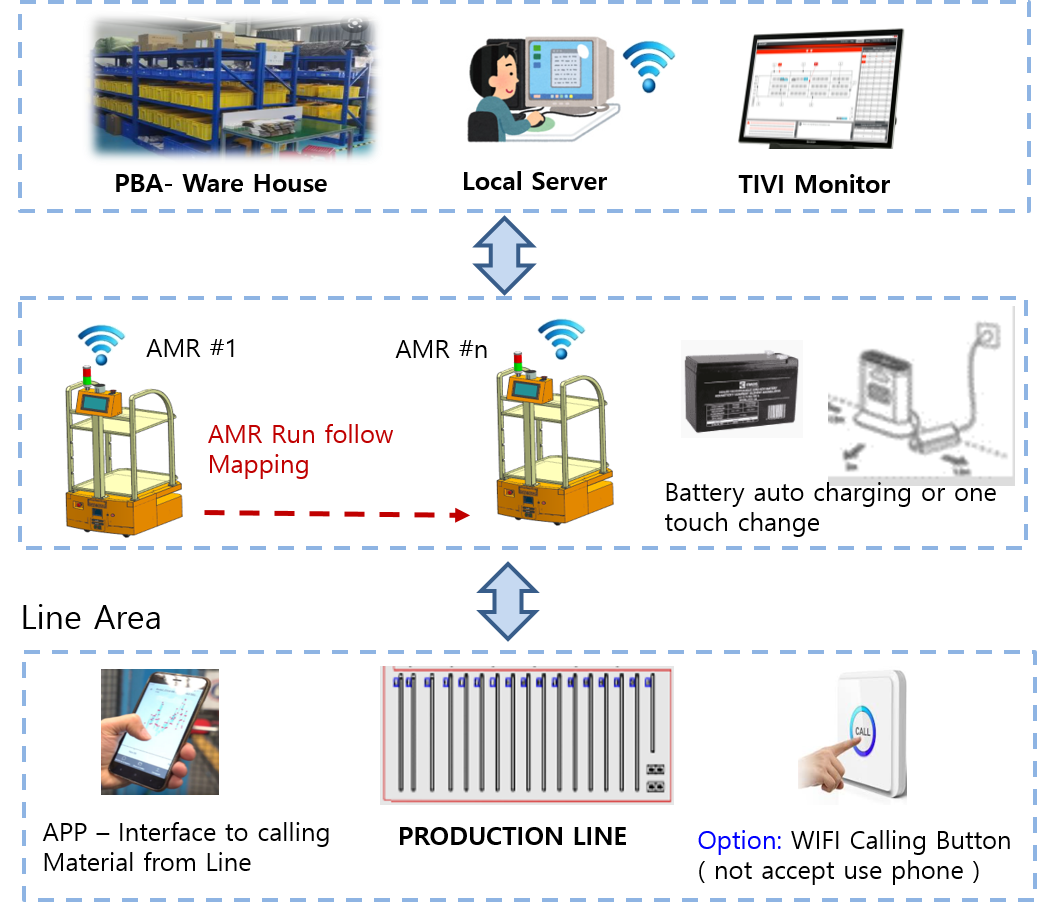

AMR Operation Solution

AMR management system will be controlled by 1 local Server

AMR is communicate with Server to get Data ( Requirement from Line or production plan ) for operation

Local Server receive Requirement from Line or by plan to control AGV operation

AMR operation result and moving status will be record into Local Server and Showing on monitoring

Material Calling by Mobile Phone APP . Which will be set into Leader Line Hand Phone

( APP interface can input Line Number , Model , Q’ty ...ect )

Communication type: WIFI , IIoT ,

• Model: AMR21 – DL

• Max size (mm) : L650 x W500 x H1100 ( Can change by actual request )

• Loadable weight (reference) Max 50 Kg

• Running speed (No loaded) * Variable depend on towing weight: 25 ~ 40 M/min of adjustable by Touch screen

• Guidance Type Laser LIDAR Sensor and TFO CAM ( No use Tape )

• Operation Interface and Software Touch screen interface to control directly or Web interface to control from PC

• Running direction Forward - Rotation 90 - 180/360 degree

• Optimize for wave Running status when Floor un-flat

• I/O Connection Auto control Slide Door

• Loader Type Load directly into AGV Rack , Possible to change Rack

• Lay out setting Flexible for setting running way by set Mapping

• Setting Method Setting by Computer or Touch screen

• Function Laser LIDAR detect objects – way guidance, Work position,

- Door Remote control

- Melody unit: Installed (3 sounds type)

- Operation: all parameter- JOB- ID Station setting by touchscreen

- Display and monitoring operation status by Touch Screen

• Battery Charging Time: 4 Hour or One Touch, Job change by Spare BAT

• Battery Running Time : Li_ Battery 37VDC – 20 Ah , Running time 6~10 Hour

• Battery Charging: Auto Charger

• ESD Connection : Wire connection and Ball Head touch into Floor

OPTION :

- Wireless calling button to call AMR from Line

- Monitoring and Control System

Main Operation Process

Delivery Material from WH to Line -> Return the Finish Goods from Line to Marking

SYMKOS AMR - SMART FACTORY SOLUTION