CODE READING/

COUNTING MACHINE

We provide a wide range of professional services to meet your needs. We promise to provide every service with a smile, and to your highest level of satisfaction.

Simple process

High Precision

Cost saving

SYMKOS

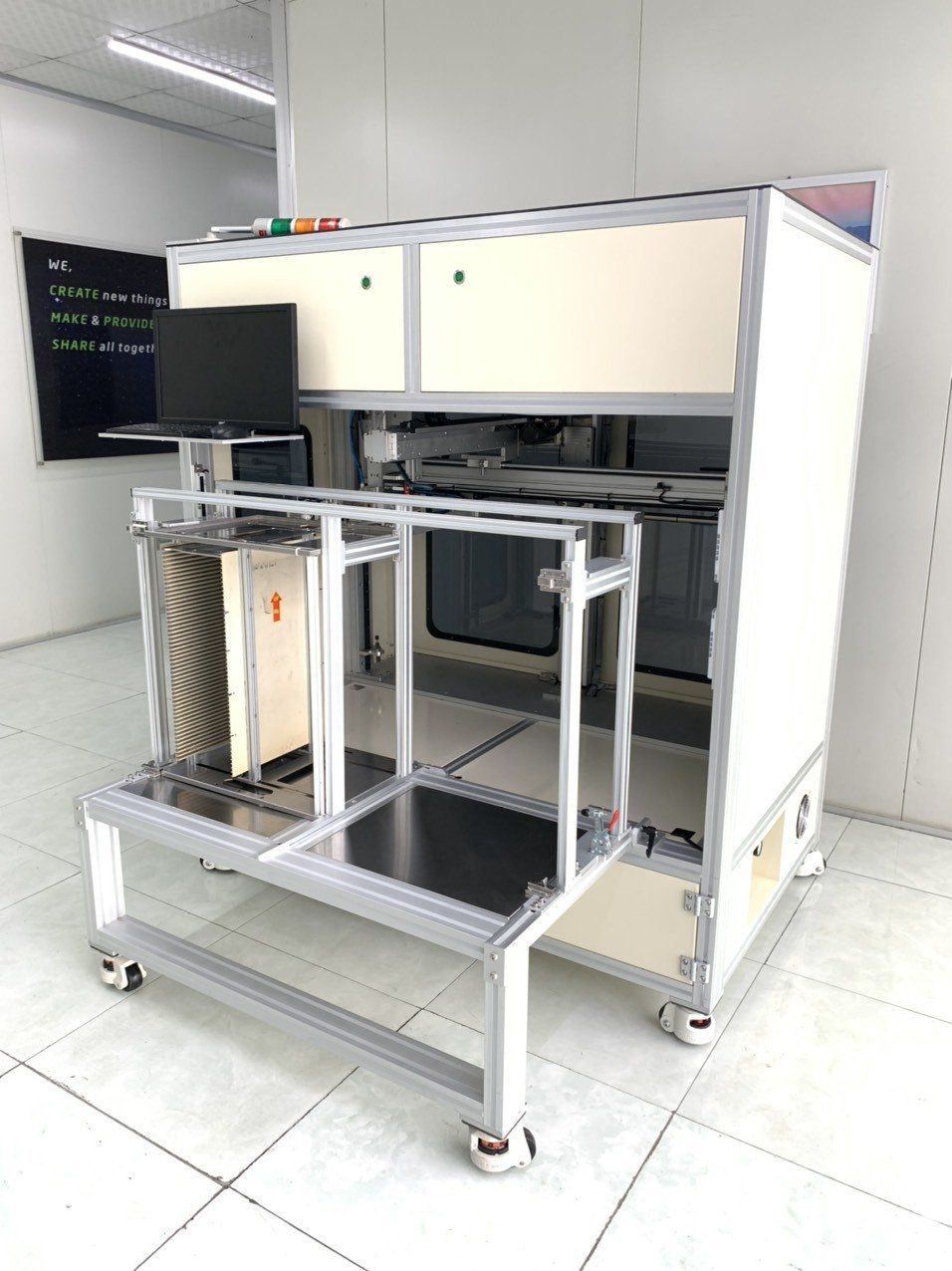

CODE READING MACHINE - MAGAZINE TYPE

SYMKOS - QR Code reading machine ( Magazine Type)

Main Structure

1. Auto Reader motion part

- Apply single Robot motion X-Y-Z-R Axis for Flexible setting of reading code Position

- Flexible reading for TOP/ BOT side base on setting

2. Carrier Load-unloading station

3. Reading part

- Apply Cognex Reader

5. Control Unit

- Flexible setting model/job change

- Auto alarm and stop machine when no reading

Operation Process

Manual LD Carrier into Reading code station -> Auto Reading code TOP side and Barcode A series of Carrier -> Auto Reading Code of BOT Side products and Barcode B series of Carrier -> Auto reading Barcode C series of Carrier and Summary all Barcode Data to show on monitoring -> Record Data -> Manual unloading Carrier

Easy Usage - Easy Setting - Easy Job change - Easy Review

- Model : ARC-22

- Electricity : 220V 50-60Hz , 1KW

- Weight : 60Kg

- Machine Size: L650 x W600 x H700

- Carrier Max Size(mm): L350 x W280 x T10

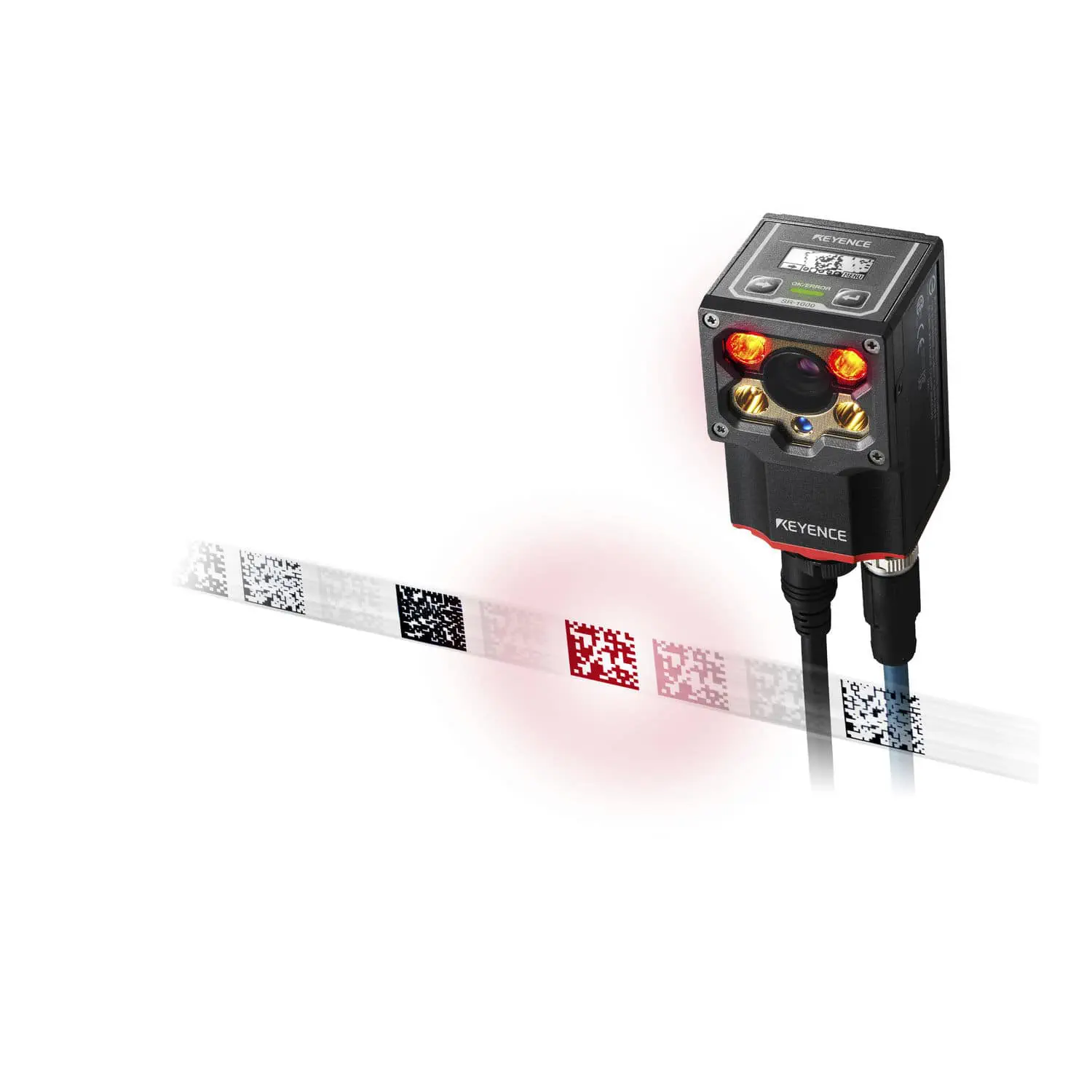

- Code Reader: Keyence SR-1000

- QR Code size (mm): 1.5x1.5

- Q’ty reading 1 time: 2 pcs

- LD/ULD Carrier into Mc by 1 OP

- Data saving to Excel file

- Machine Cycle time: 26 Sec with 40 pcs of 1 carrier

- Station Capacity: 98K/ Day of 20 hour working 90% Per

SYMKOS

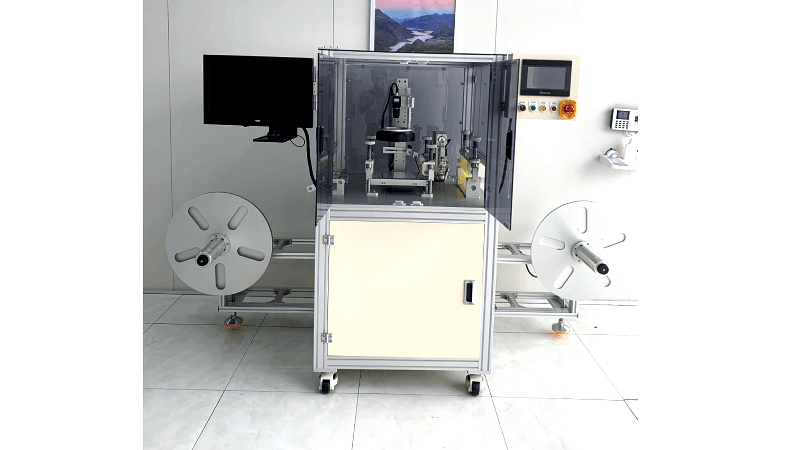

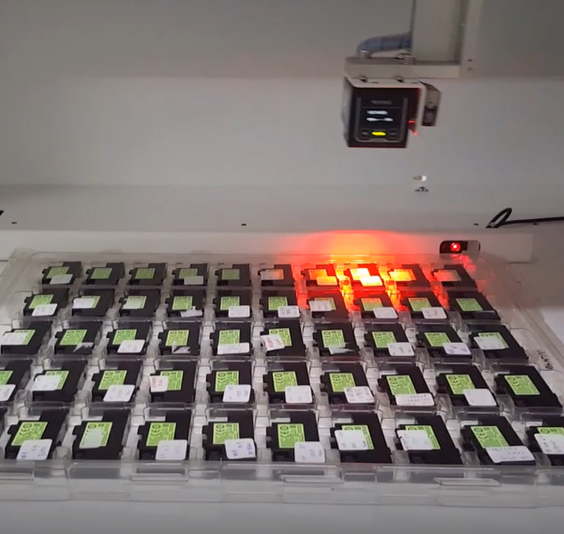

AUTO CODE READING MACHINE - TRAY TYPE

1. Auto Transfer and Guiding part

- Time belt conveyor to transfer each tray

- Flexible conveyor size adjustment by tray size

2. Auto Reader motion part

- Apply single Robot motion X-Y Axis -> for Flexible setting of reading code Position

- Reader can adjust Z axis position

3. TRAY LD-ULD station

- Auto Load 1 tray into transfer conveyor

- Auto unload each TRAY for stacking after reading

- Load/unload TRAY Stacking during running

4. Reading part

- Apply KEYENCE Reader . Series SR-1000

- Auto Focus while change FOV of Reading

5. Control Unit

- Flexible setting model/job change

- Auto alarm and show unread PCB on the monitor

- Save data in computer, Export report CSV file

- Auto alarm and stop machine when no reading

Operation Process

Manual LD TRAY Stacking into loading station -> Auto load 1 by 1 TRAY into transfer conveyor -> Auto Code Reading on TRAY -> Auto transfer TRAY into unloading station -> Auto Stacking TRAY -> Manual unloading TRAY stacking ->

Model : S-AC17-3

Electricity : 220V 50-60Hz , 0.5Kw

Weight : 150Kg

Machine Size: W620 x L1200 x H1100mm

Tray Size : Max W400 x L550 x H170mm

SYMKOS Code reading - Tray input

SYMKOS

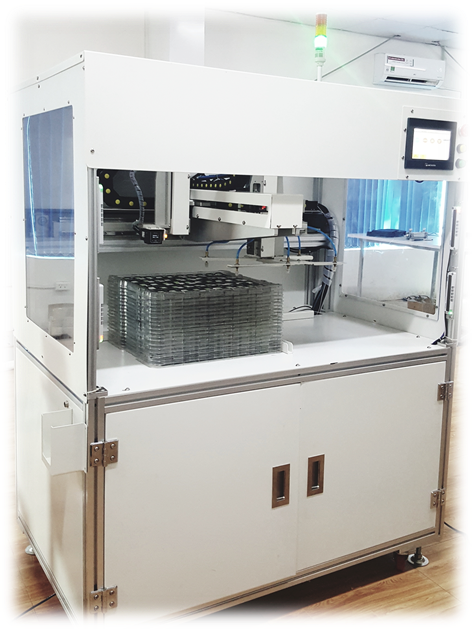

AUTO COUNTING MACHINE

Main Function of Hardware

Loading/Unloading : 270mm-height Loading Space

Auto Control and Alarm for end of product Lot

Auto Tray Pick-up one by one and transfer to unloading position(Tray transfer time: 5 Sec)

Tact Time of Checking and Barcode Reading : 0.5sec

Flexible for Job change / Model change by X,Y,Z axis Motion ( Z Motion Stroke: 320mm)

Tray fixing by Centering which can adjust manually for all model

Short Job change time for different model by HMI screen

Communication by RS232 , RS485, Ethernet , TCP/IP to server

Data Management S/W : Record barcode data or Image checking/counting products and transfer CSV/excel file data to Server

Main Function of Operation

Reading/Vision counting by Enable/Disable 2 in 1

Product Counting : Based on image counter (Applying for No-barcode product)

Product Quality Inspection for simple defect: Vision Image Inspection based on program setting by Limit sample

Printing Quality Inspection: The optical character recognition (OCR) can read up to 80

characters. (Capable of case-sensitive reading for capital letter or small letter)

Product Barcode Reading: The 1D/2D code reading function is compatible with the

following code types and can read up to 80 characters. 1D code: 25 types

(Industrial 2 of 5, EAN-13, Code 39, etc.) 2D code: 2 types (Data Matrix ECC 200, QR Code)

Model : S-AC17-3

Electricity : 220V 50-60Hz , 0.5Kw

Weight : 150Kg

Machine Size: W620 x L1200 x H1100mm

Tray Size : Max W400 x L550 x H170mm