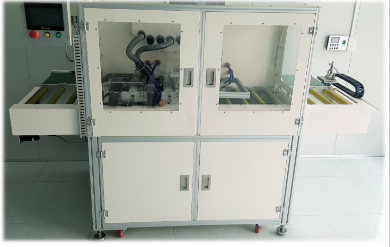

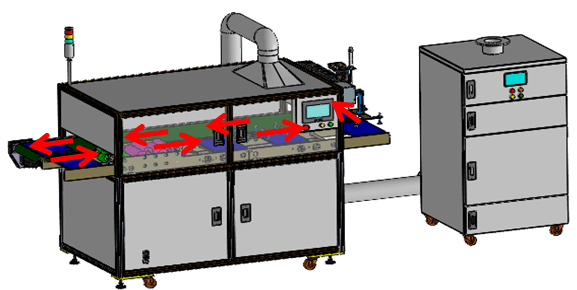

1, Roller Cleaning Part

- Machine designed separating with L/R cleaning part

- Water and Rolling together in during wheel cleaning

- Easy check and Maintain , easy Cleaning Roller by 1 touch

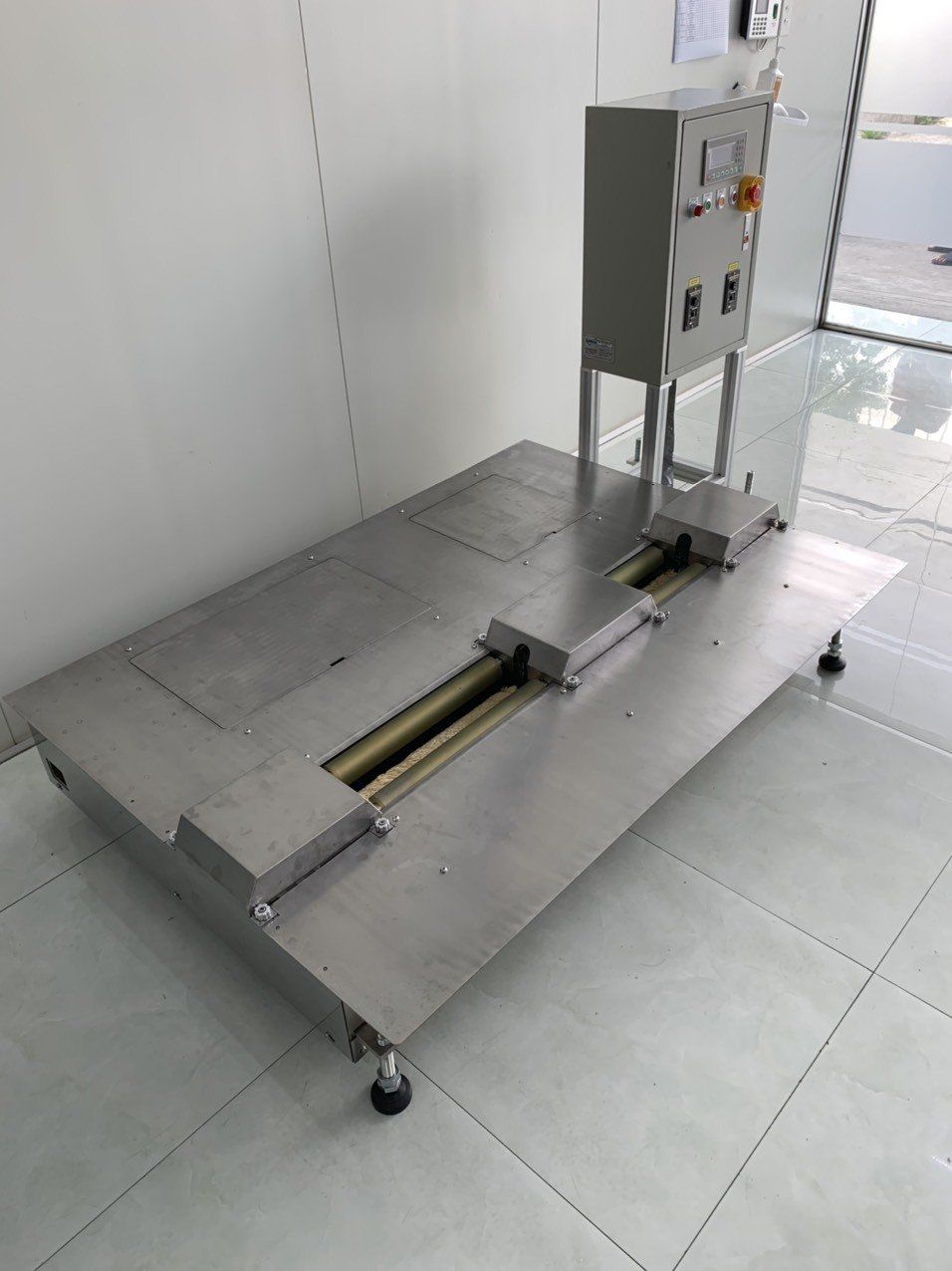

2, Water Tank

- Tank Volume by 15L , Easy See control water status from outside

- There are Sensor to control Upper and Lower Water Limit in the Tank

- Tank is keep the cleaning water. Which was passed from filter part

- Water will be recycle and filter after cleaning wheel

3, Pump and Filter Part

- 3 levels for water filter after cleaning to get cleaning water to return tank

- Filter layer #2,#3 will be replace 2 ~3 month by 1 time

- Filter layer #1 will be check and manual cleaning to replace in 2 week / 1 time

- Easy use with 24VDC water Pumper

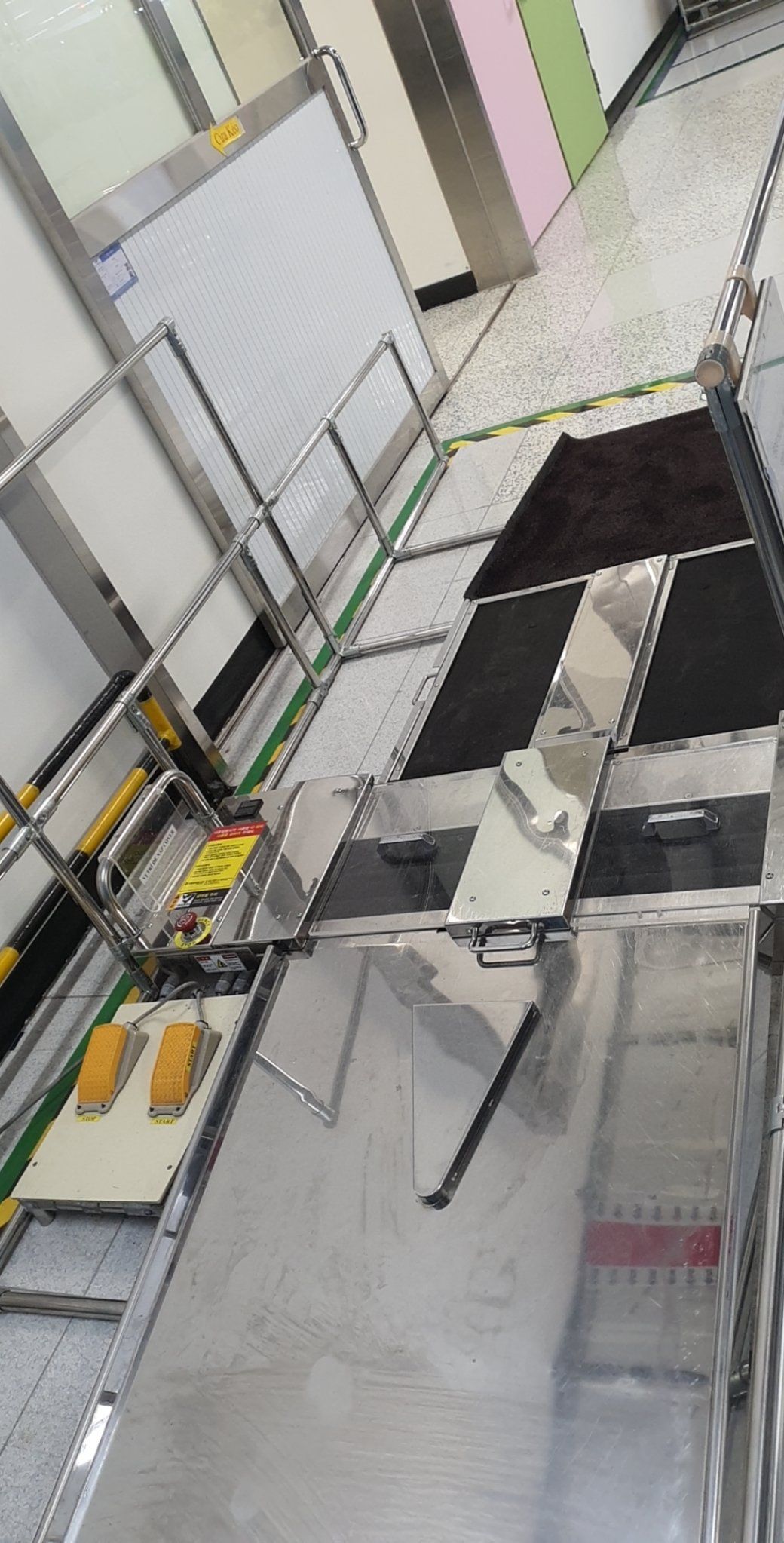

4, Input and Output floor

- Apply mat to make wheel dry after cleaning

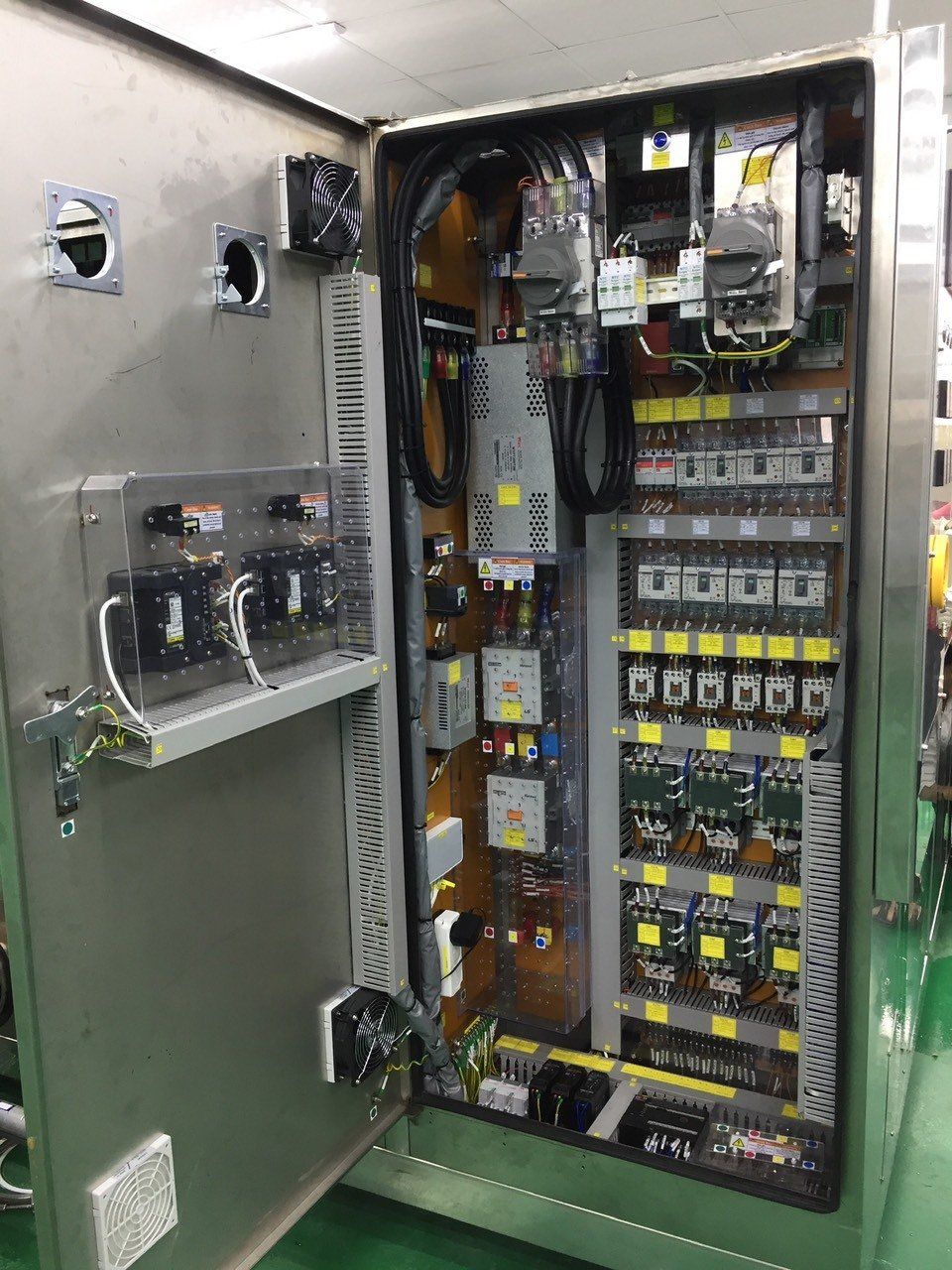

5, Control Unit

- Easy Setting and application

- Auto Alarm for limit water, and remind cycle of tank cleaning, water change, maintaining