PARTS FEEDING /

INSERTION MACHINE

SYMKOS high-strength, simple operation Auto Parts Feeding Machine. The machine can be customized and modified to meet the different needs of customers with professional services

High Precision

Time Saving

Time Saving

Optimize Production

Optimize Production

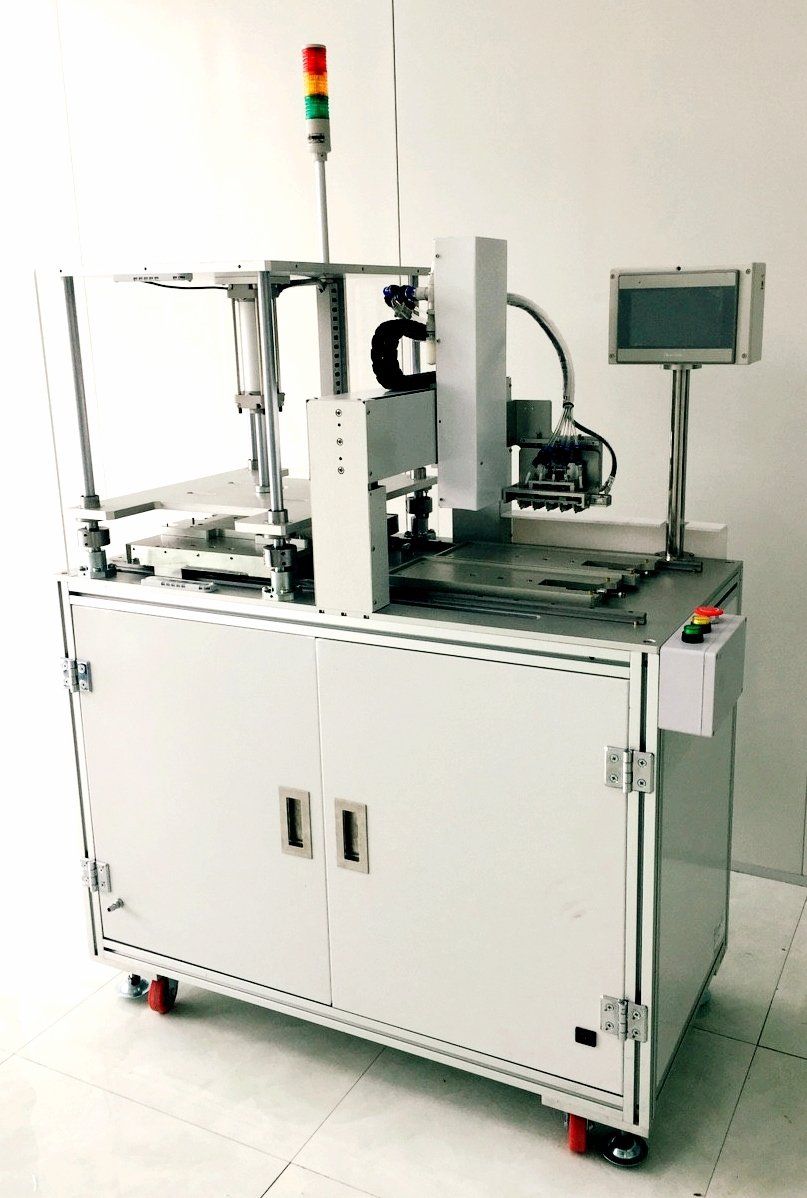

Part Insertion Machine V1 (PCB/FPCB)

ButtonSYMKOS

PCB/ FPCB AUTO INSERTION MACHINE V1

SYMKOS

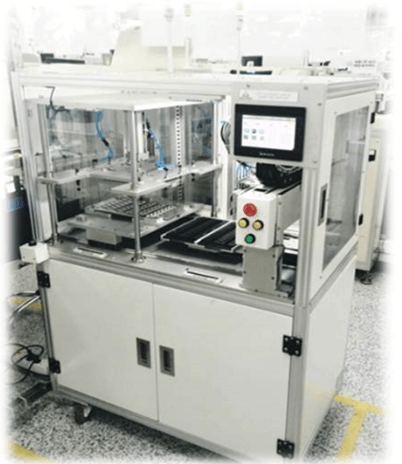

PCB PART INSERTION MACHINE V2

SYMKOS

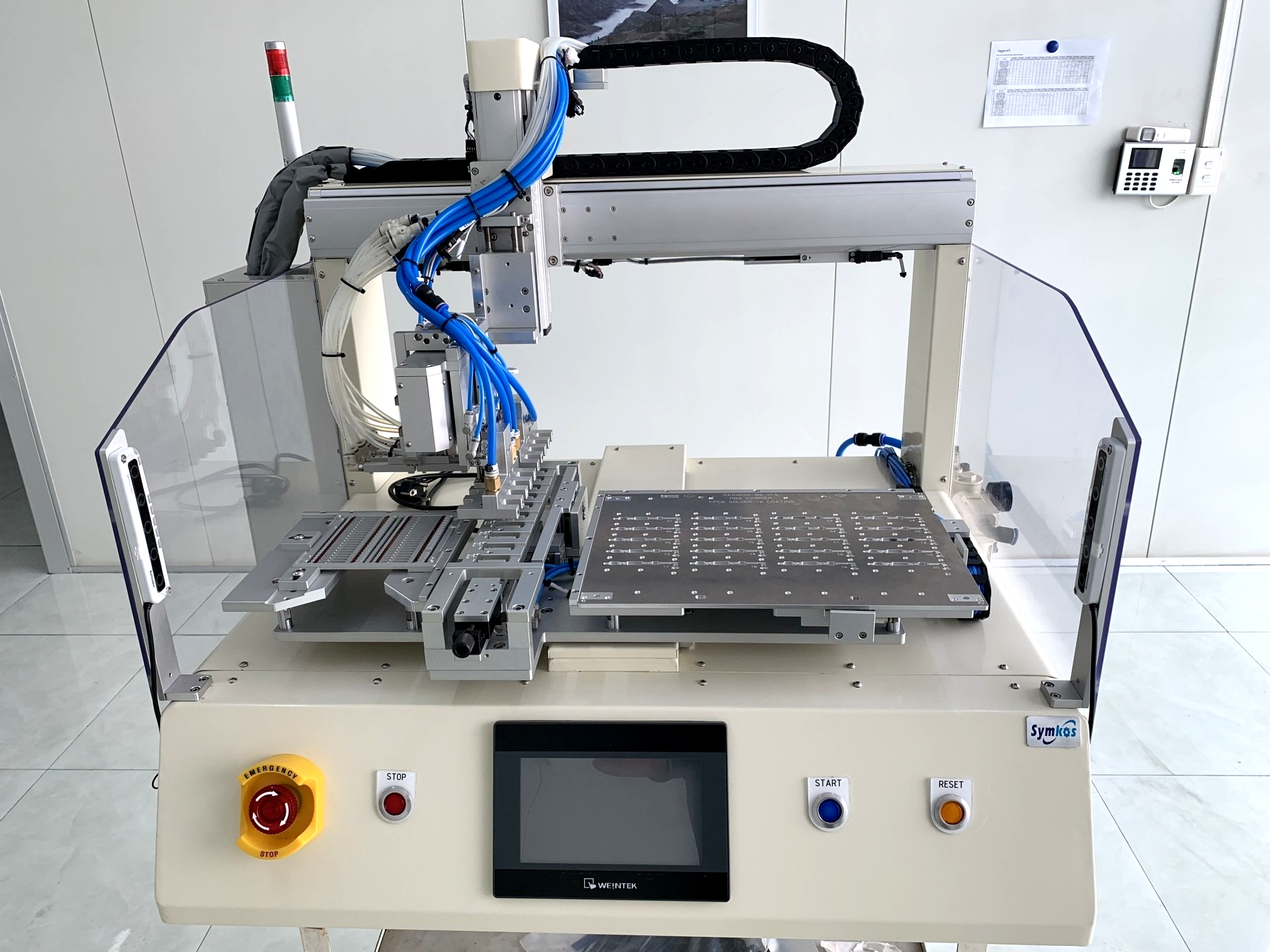

PCB/FPCB AUTO INSERTION MACHINE V3

SYMKOS

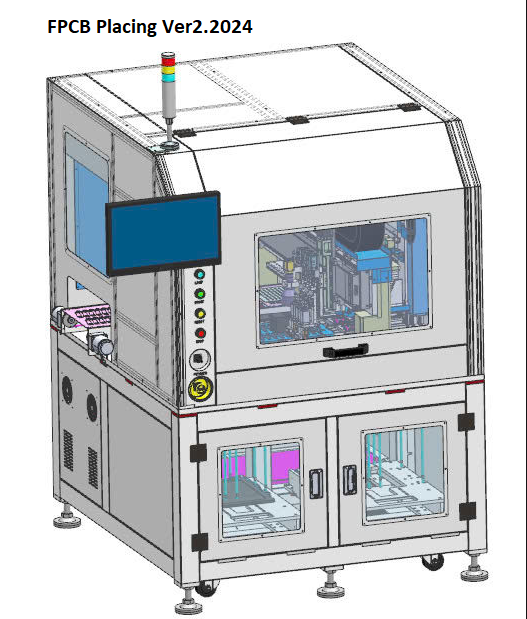

FPCB AUTO INSERTION MACHINE V4

SYMKOS