AUTO ATTACHING MACHINE

Auto attaching machine has been smart solutions for improving working capacity in many manufacturing factory . Easy to change mould, suitable for different sizes of products, save a lot of labour cost..

Tape Attaching

Label Attaching

Barcode Attaching

SYMKOS

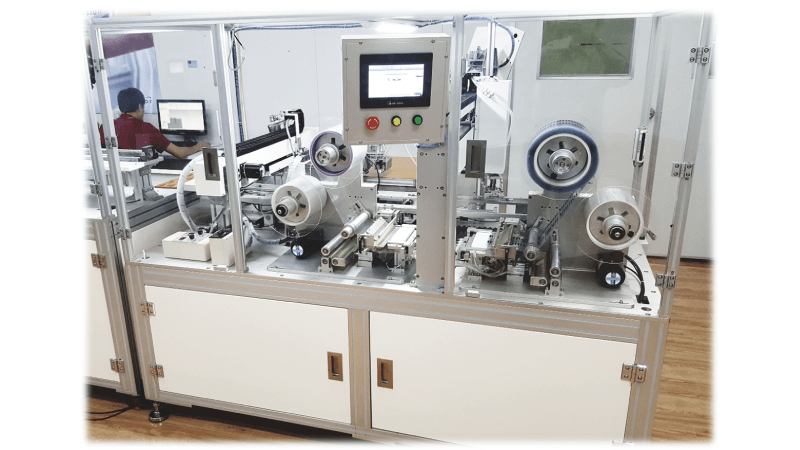

AUTO TAPE ATTACHING MACHINE (SHEET TYPE)

√ A lot of tape loading a time into machine

√ High Productivity (6 pieces attaching on 1 attaching jig)

√ High machine performance by Full Automation line

√ Flexible to application for all kind of Tape attaching

In case of full auto line for many kinds and many quantity of tapes

√ Excellent LOB(Line Blance) by relocating stand alone machines

√ Easy model change by changing the tape quantity on the top and bottom side

√ Easy machine maintenance

√ Simple machine layout & easy layout change

√ Easy Job Change

+ Model S-AT2018-1

+ Size(mm): L 2300 x W 1000 x H 1400

+ Weight: 400 kg

+ Power: AC 220V, 3KW

Applicable Tape Size

+ Min. Size including cover sheet(mm): L 10 x W 4 x T 0.07

+ Max. Size(mm): L 70 x W 60 x T 0.07

+ Max. Cover Sheet Size(mm): L 200 x W 150 x T 0.07

Machine Cycle Time: 1.5~2.0 sec

SYMKOS

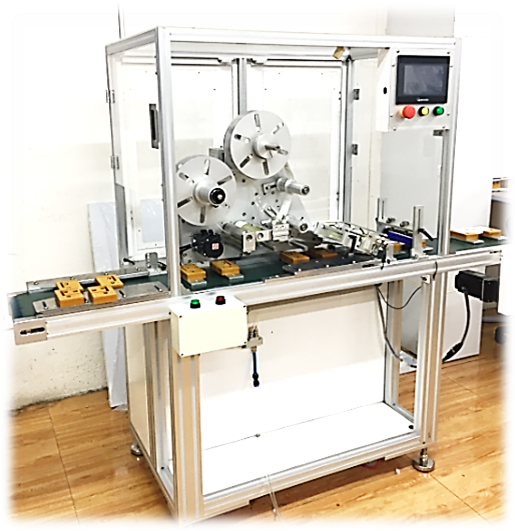

AUTO SILLICONE TAPE ATTACHING

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Strong Point of the Machine

Can attach 1~6 Tapes on the carrier jig 1 time

Easy setting and easy application

Easy change material roll

Flexible to application for all kinds of Silicon tapes

Main Structure

Jig Table , Auto Clamp Jig part: Make centering Carrier before attaching Tape

Y/Z –motion axis part for feeding part motion: Auto Feeding and motion Tape

Feeding part: Feeding 4 silicon roller together by 1 time

Pressing and Cutting part: Press tape into carrier and cutting at the end point

Control Unit: PLC, HMI for setting and Job change flexibly

Safety sensor

+ Model : S-ACT2018-1

+ Machine Size: (mm): L700 x W550 x H600

+ Weight: 200kg

+ Power: AC220V, 1KW

+ Carrier Jig Size: L300 x W270 x T7mm

+ Biggest Tape Size for Application (mm): L290 x W20 x T0.07

+ Smallest Tape Size: L100 x W4 x T0.07mm

+ Production Capacity : 2,900 Carrier / day (20hr)

SYMKOS

AUTO LABEL ATTACHING MACHINE

1. Transfer conveyor ( JIG conveyor ): Special belt, Guiding Jig and Auto Centering Attaching Position

2. Y,Z –motion axis part: Easy – Flexible to Adjust Feeding Position into attaching Position

3. Centering Part: Feeding Centering , attaching position Centering for exact attaching position

(Laser sensor to control JIG Moving Position and Label feeding Position)

4. Feeding Part: Label feeding and collecting main cover of label.

Flexible matching between Feeding speed and conveyor JIG speed for Cycle time optimization

5. Pressing part: Press Label to make sure Label no have Air inside after attaching

6. Control Unit: PLC, HMI screen for setting and Job change

7. One touch JIG for Each Model. Total Q’ty 10 JIG / 1 Model

8. Set up Feeding Position by HMI screen

9. Easy feeding limit adjustment by each Model

+ Model : S-AL18

+ Size(mm): L1800 x W900 x H1650

+ Weight: 200kg

+ Power: AC220V, 1KW

+ Input Product Max Size (mm) : L190 x W130 x T30

+ Biggest Label Size for Application (mm) : L180 x W120 x T0.7

+ Smallest Label Size: L60 x W20 x T0.2 mm

+ Label Size(mm): Max D220 x W150

Capa

+ Daily Capa: 23K~17K/day(20hr, 95% efficiency)

+ Tact time: 3~4sec/case

Option

- Option #1: Auto Loading Production to attaching label

- Option #2: Auto Un-loading Product and stacking after attaching Label

SYMKOS

AUTO BARCODE ATTACHING MACHINE

- Flexible to change for Different Models

3 Direction Motion (X Axis / Y Axis / Z Axis)

LCiA Design to Combine 4 Positions Label by 1 Motion X, Y axis

Precise Head Adjustment of X, Y, Z axis by HMI screen

- Shorter Job change time by re-loading the program

Auto PCB Loading and Unloading (10Cm Loading height: 60~80 PCB sheets/time )

Combine Auto Bar code Reading after Attaching

Machine Size(mm): W600 x L1000 x H800

Label Roll Size: D 20~120mm

Electricity: 220V 50-60Hz , 0.5Kw

Weight: 150Kg