VISION MACHINE

Advanced machine vision & industrial barcode reader systems deliver instant improvements to any manufacturing process, enabling products to be made at higher speed, without defects and at lower cost

Effective Solution

Consistent and Accurate

Various Application

SYMKOS

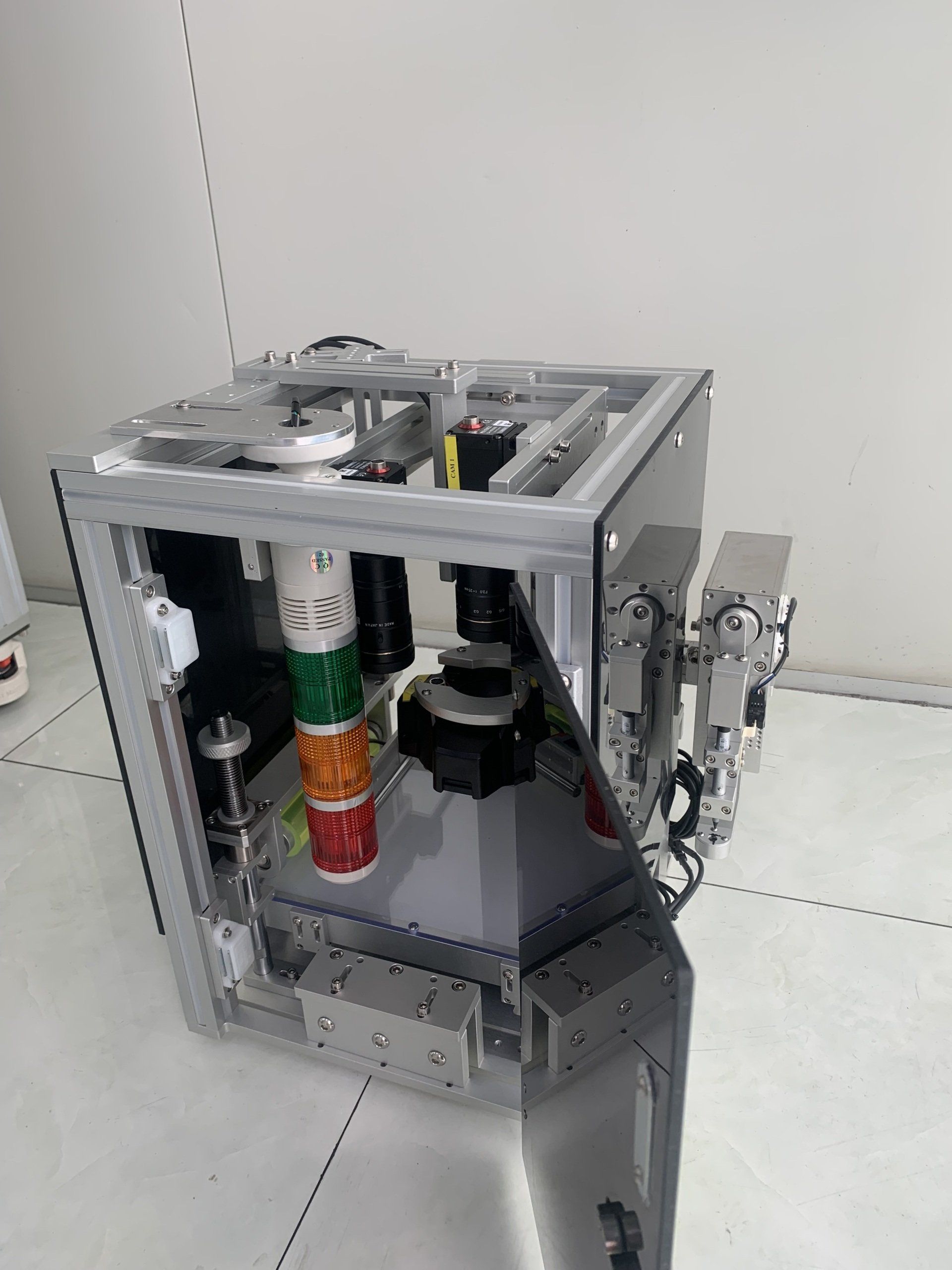

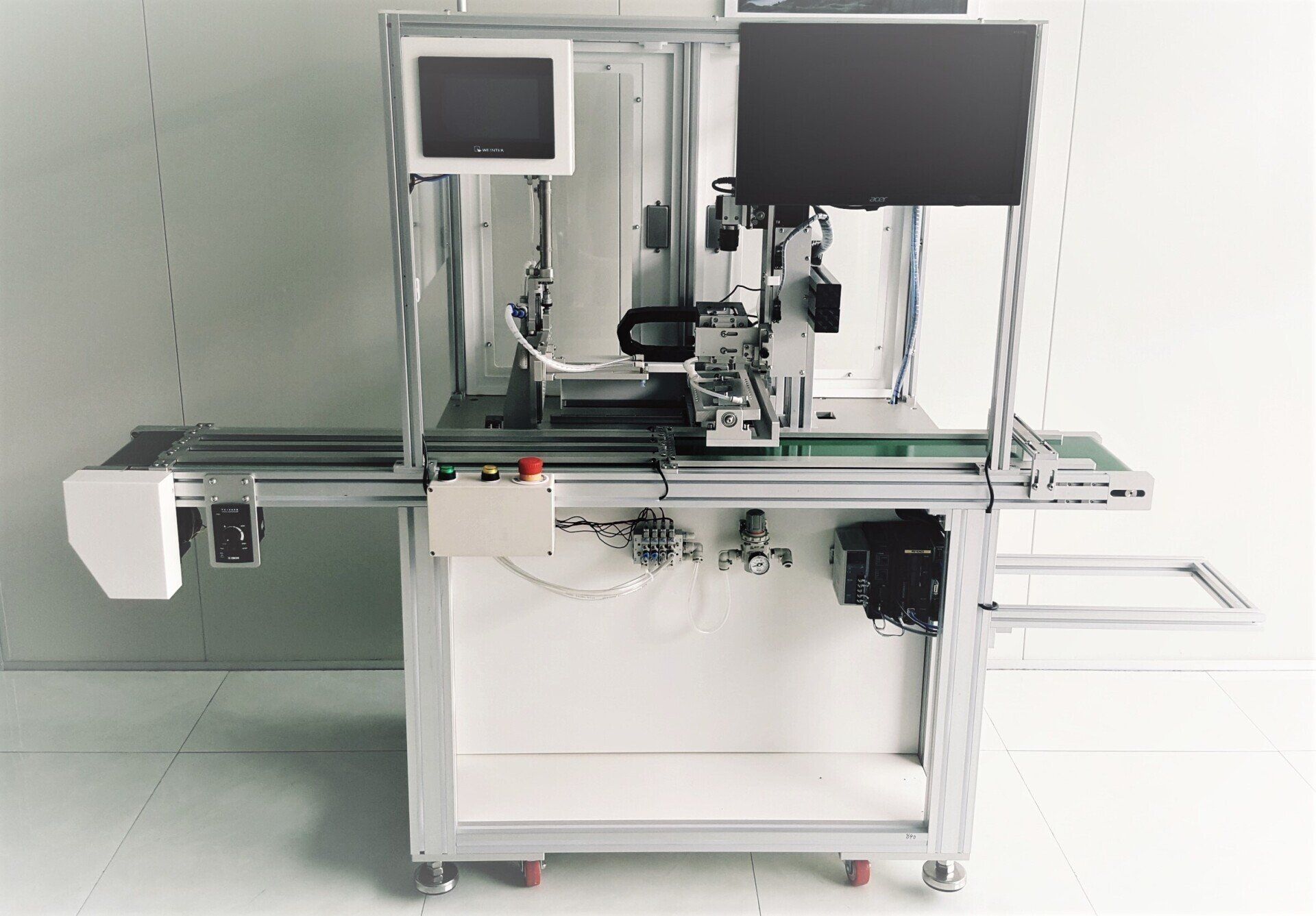

VISION MACHINE - 4 CAM BUILT IN

Vision Inspection Machine - 4 CAM Built in

1. Mechanical Part

• CAM Fixture: Easy Job change for a short time by one touch

• Auto guiding and tape feeding structure

• Pen marking part: Soft marking & tip cover

2. Vision Part

• Based on List Shinsung-VS21-2CAM-5M

• BOT/TOP Lighting Part

3. Auto Marking

• Flexible to setting Position Marking for NG Product, and Classify NG type by Length of marking point

• Use standard Pen , Auto close Pen while no use

4. Control Unit

• Easy setting and change Model , Change parameter of machine by HMI Monitoring for display

(2021) 4- CAM Built in line Vision Inspection:

• Model : VS21-4CAM

• Electricity : 220V 50-60Hz , 0.5Kw

• Camera: Camera , 4 Set

• ROI for inspection(mm): N/1

• 1 shot inspection tact time: 350msec

SYMKOS

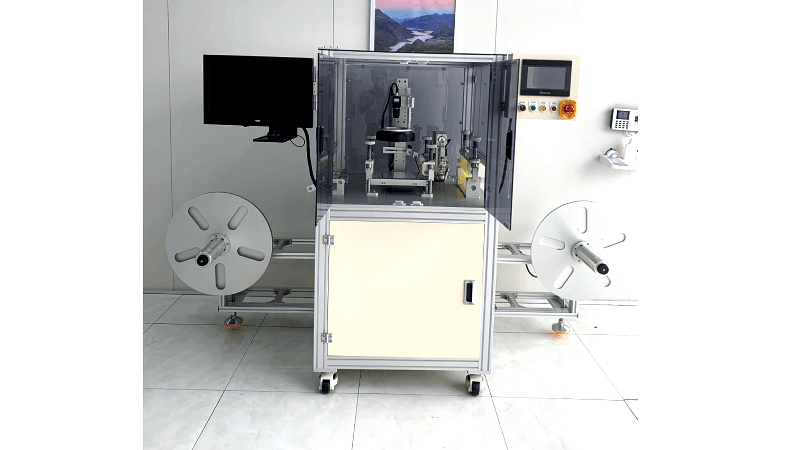

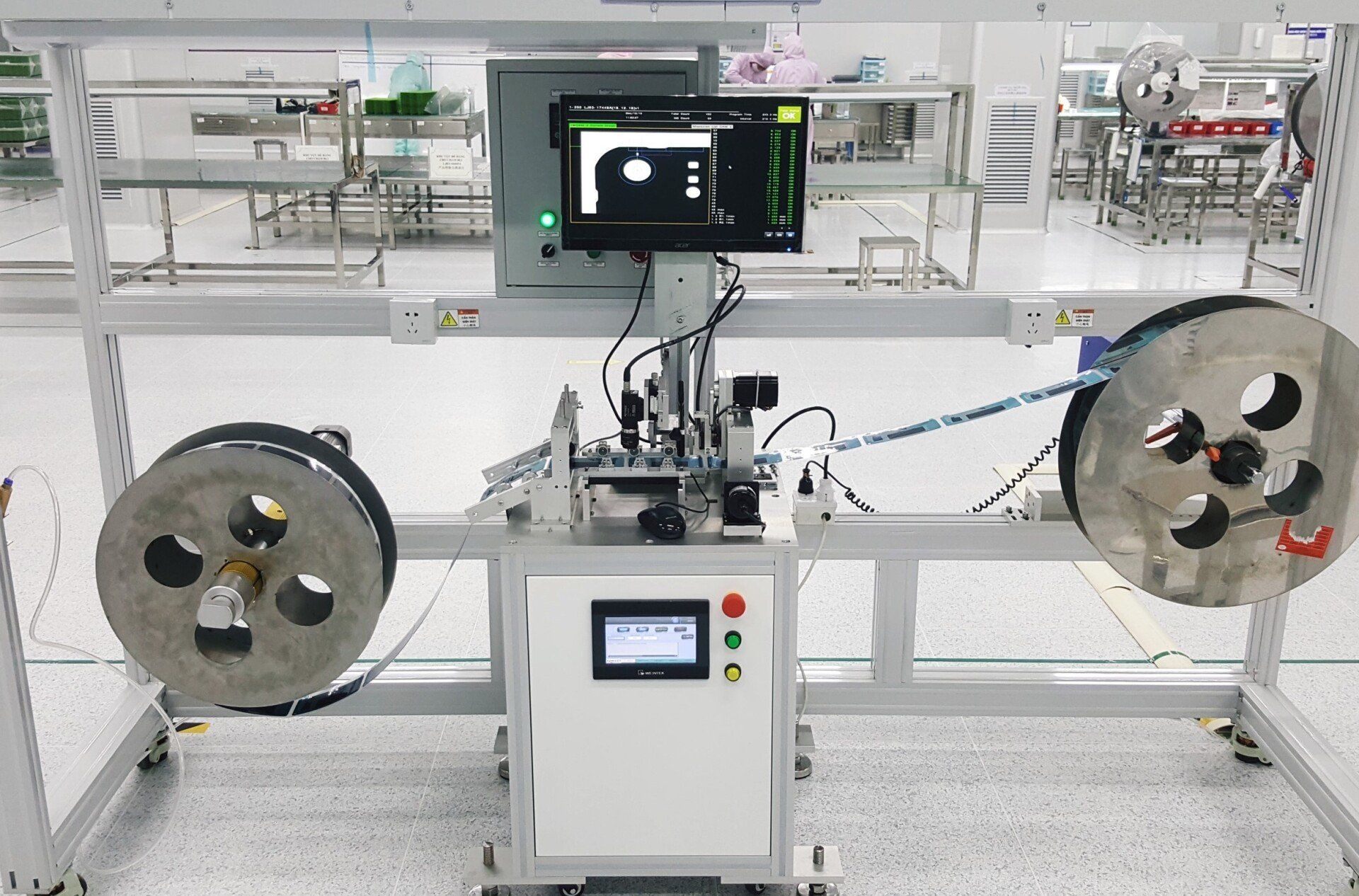

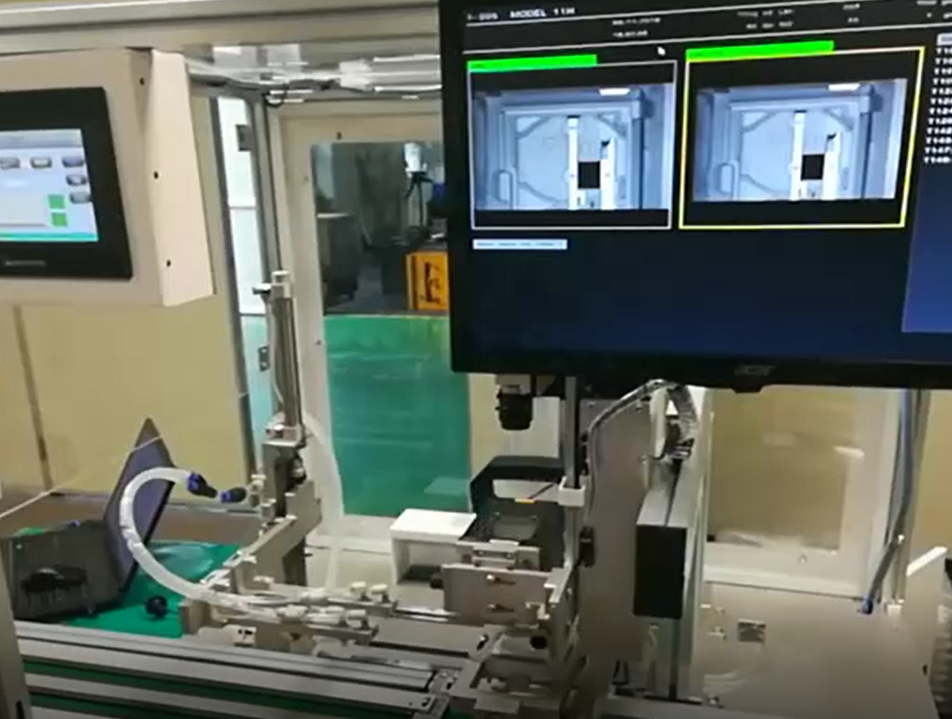

VISION MACHINE - FOR WINDOW TAPE

Part 1: Lighting Part

- Make Lighting Background to reflect product

- Can control lighting by Volume

Part 2: Control Unit

- Easy and Shorter Job change time by re-loading the program

- Monitoring for display

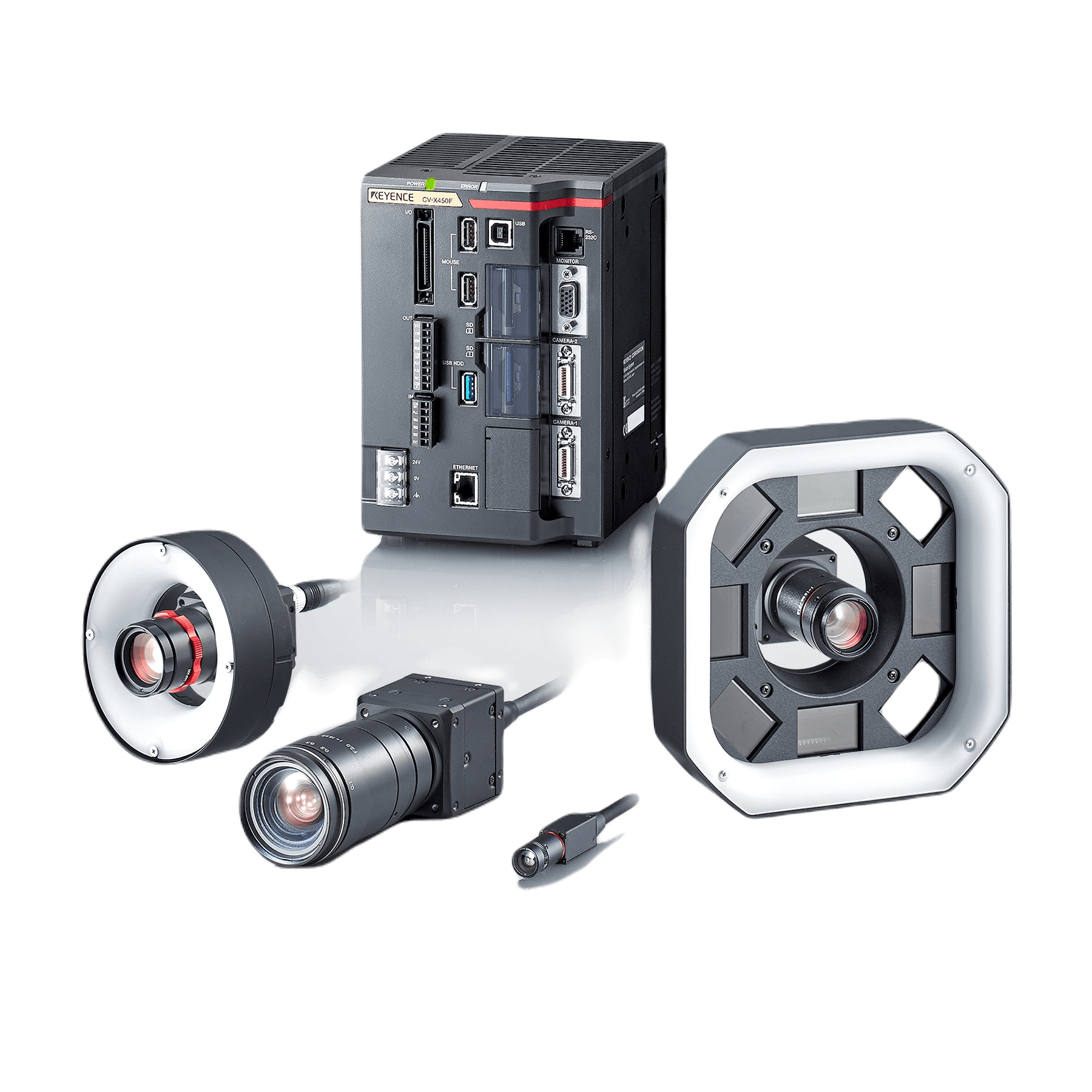

Part 3: KEYENCE Vision Part

- Camera Inspection based on Program setting

- Auto record NG Image into SD Card

Part 4: Spring Roller and Motor Feeding Part

- Pull suitable Tape moving speed before and after machine

- Keep suitable Tape tension for inspection

Part 5: Encoder part

- Measuring the Tape length moving for true position of inspection

Part 6: Auto Pen Marking

Auto Marking NG product after detecting

- Model : S-VS18-2

- Electricity : 220V 50-60Hz , 0.3Kw

- Weight : 80Kg

- Machine Size(mm): L700 x W500 x H1200

- Camera: 2M Pixel

- ROI for inspection(mm): L40 x W40 x H200

- Tact time for 1 time shot and inspection: 230ms

SYMKOS - Vision Machine for Window Tape

SYMKOS

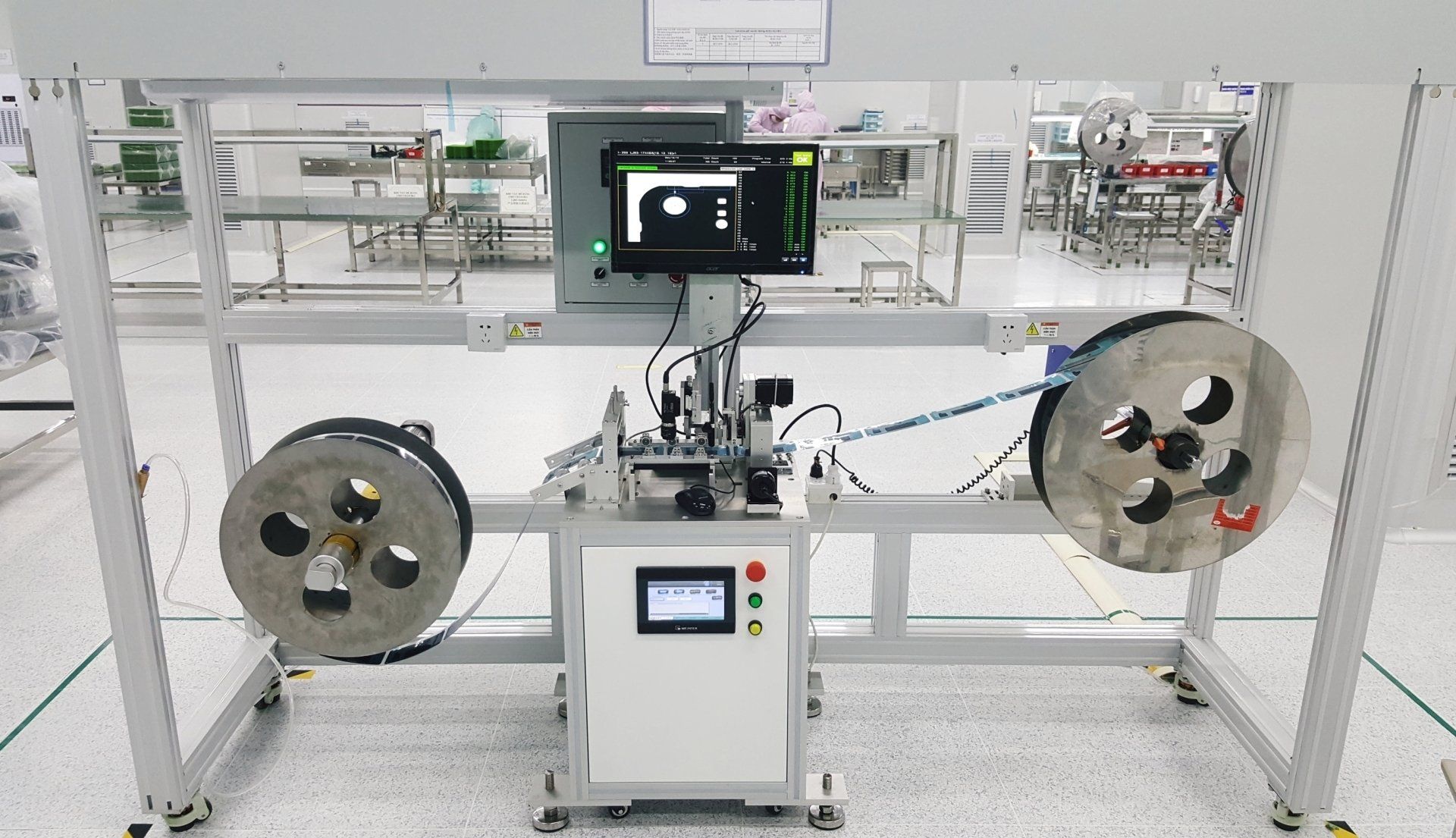

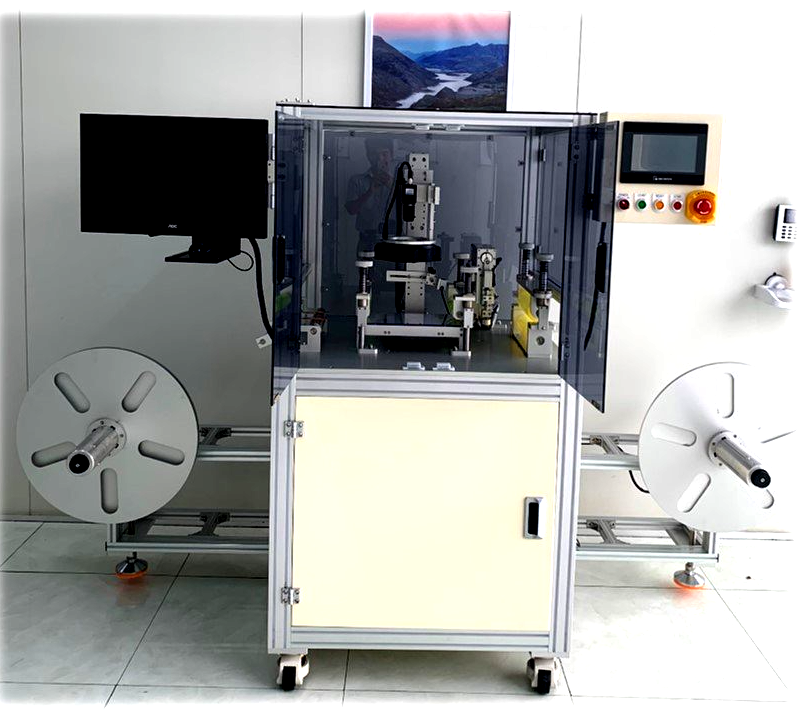

VISION MACHINE - 1 CAM STANDING

SYMKOS - Vision Machine for Window Tape

1. Mechanical Part

• CAM Fixture: Easy Job change for a short time by one touch

• Auto guiding and tape feeding structure

• Pen marking part: Soft marking & tip cover

2. Vision Part

• Based on List Shinsung-VS21-1CAM-5M

• BOT/TOP Lighting Part

3. Auto Marking

• Flexible to setting Position Marking for NG Product, and Classify NG type by Length of marking point

• Use standard Pen , Auto close Pen while no use

4. Control Unit

• Easy setting and change Model , Change parameter of machine by HMI

• Monitoring for display

• Model: VS21-1CAM

• Electricity: 220V 50-60Hz , 0.5Kw

• Camera: KEYENCE Camera , 1 Set

• Inspection range (mm): N/I

• Camera 1 shot inspection tact time: 350msec

SYMKOS

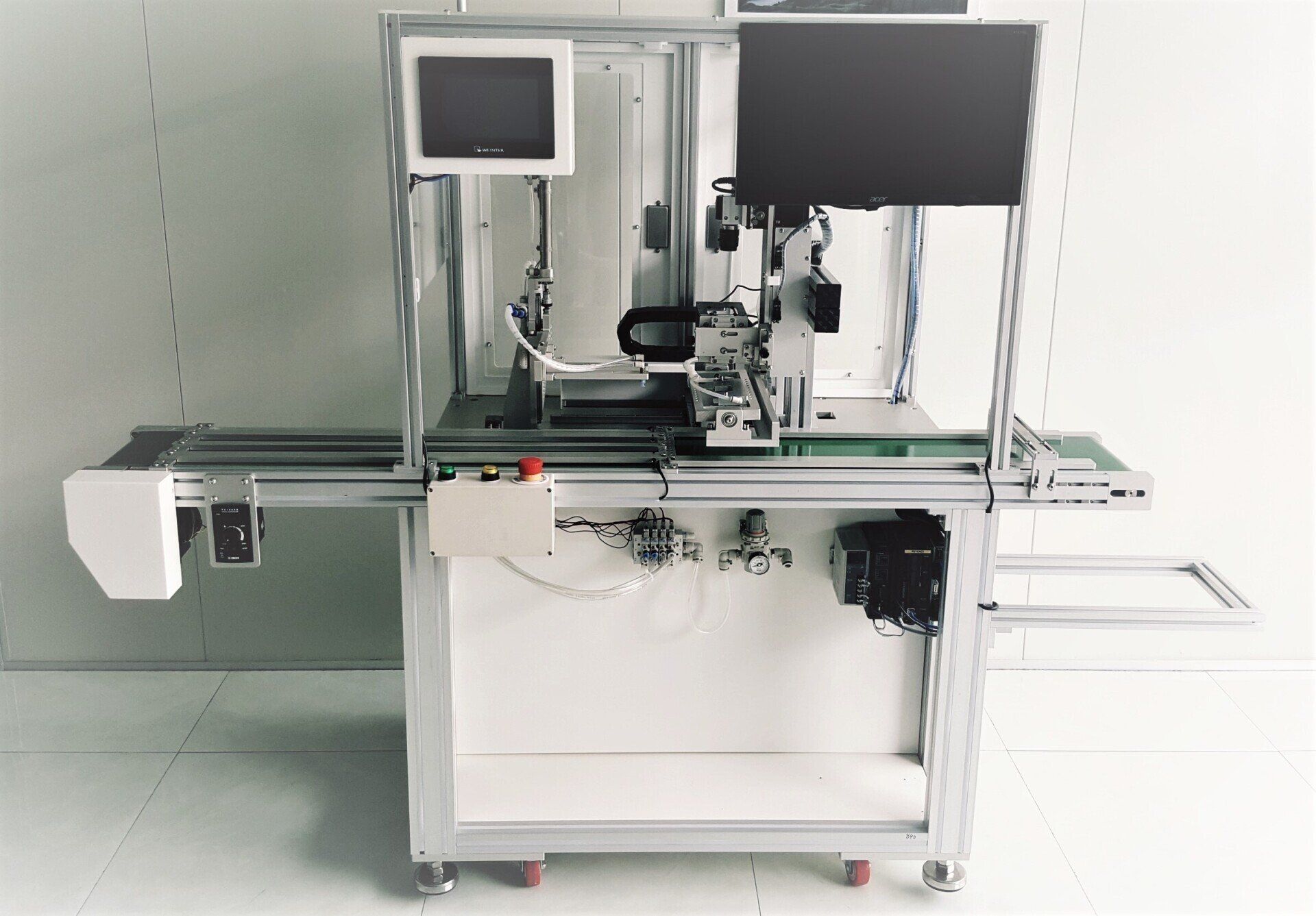

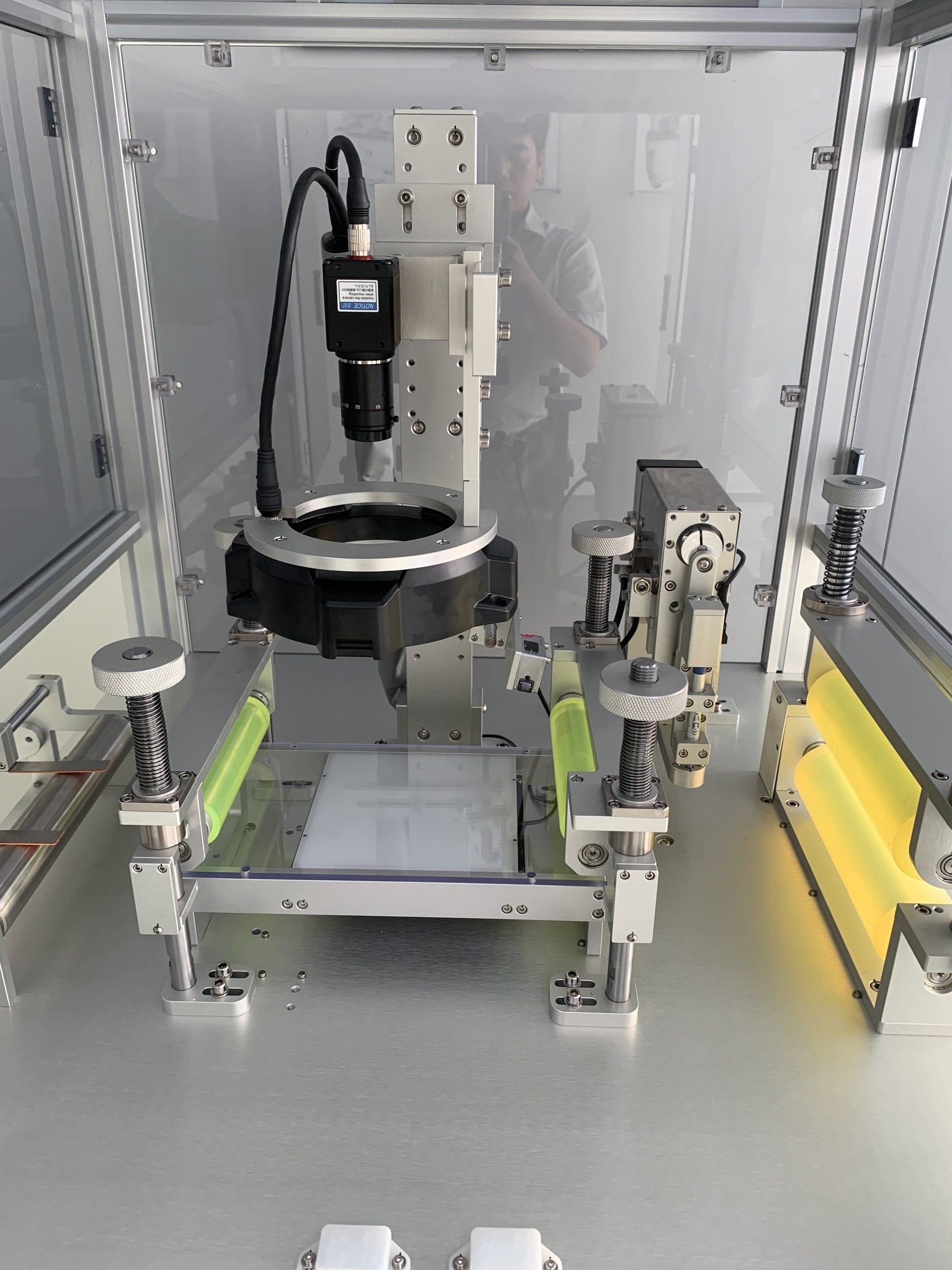

VISION MACHINE FOR TERMINAL

+ Domension & Appreance inspection

+ Maximize inspection capacity by dual input line

+ Product Top/Bottom inspection in order by reverse function

+ Apply highly reliable Keyence vision camera

+ Model : S-VS18-1

+ Electricity : 220V 50-60Hz , 1.5Kw

+ Weight : 170Kg

+ Machine Size(mm): L1500 x W700 x H1200

+ ROI for inspection (mm):L50 x W40 x H250

SYMKOS - Vision Machine for Window Tape

SYMKOS

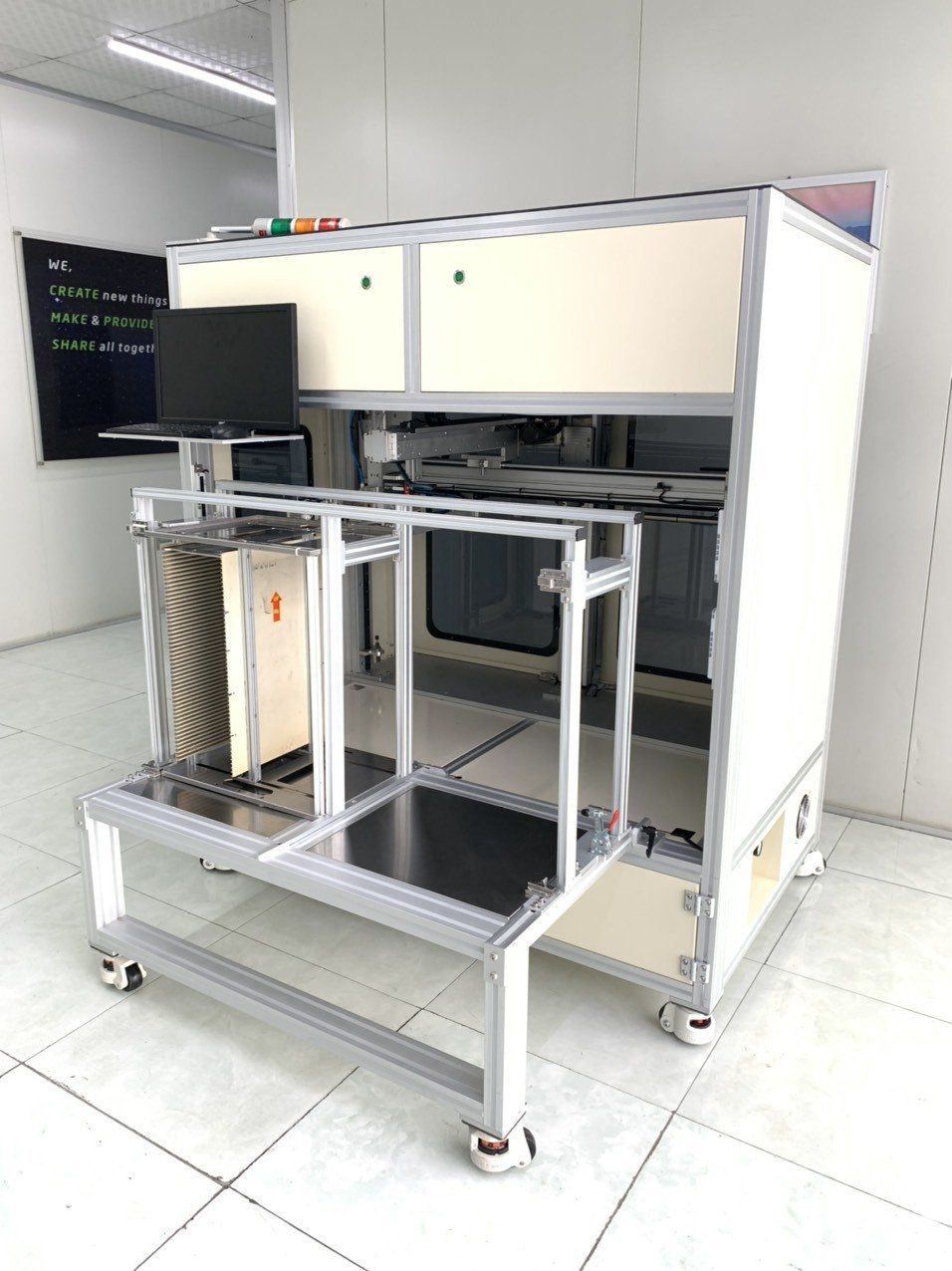

VISION MACHINE - CODE READING MACHINE

SYMKOS - Vision Machine for Window Tape

Main Structure

1. Auto Reader motion part

- Apply single Robot motion X-Y-Z-R Axis for Flexible setting of reading code Position

- Flexible reading for TOP/ BOT side base on setting

2. Carrier Load-unloading station

3. Reading part

- Apply Cognex Reader

5. Control Unit

- Flexible setting model/job change

- Auto alarm and stop machine when no reading

Operation Process

Manual LD Carrier into Reading code station -> Auto Reading code TOP side and Barcode A series of Carrier -> Auto Reading Code of BOT Side products and Barcode B series of Carrier -> Auto reading Barcode C series of Carrier and Summary all Barcode Data to show on monitoring -> Record Data -> Manual unloading Carrier

Easy Usage - Easy Setting - Easy Job change - Easy Review

- Model : ARC-22

- Electricity : 220V 50-60Hz , 1KW

- Weight : 60Kg

- Machine Size: L650 x W600 x H700

- Carrier Max Size(mm): L350 x W280 x T10

- Code Reader: Keyence SR-1000

- QR Code size (mm): 1.5x1.5

- Q’ty reading 1 time: 2 pcs

- LD/ULD Carrier into Mc by 1 OP

- Data saving to Excel file

- Machine Cycle time: 26 Sec with 40 pcs of 1 carrier

- Station Capacity: 98K/ Day of 20 hour working 90% Per

Slide title

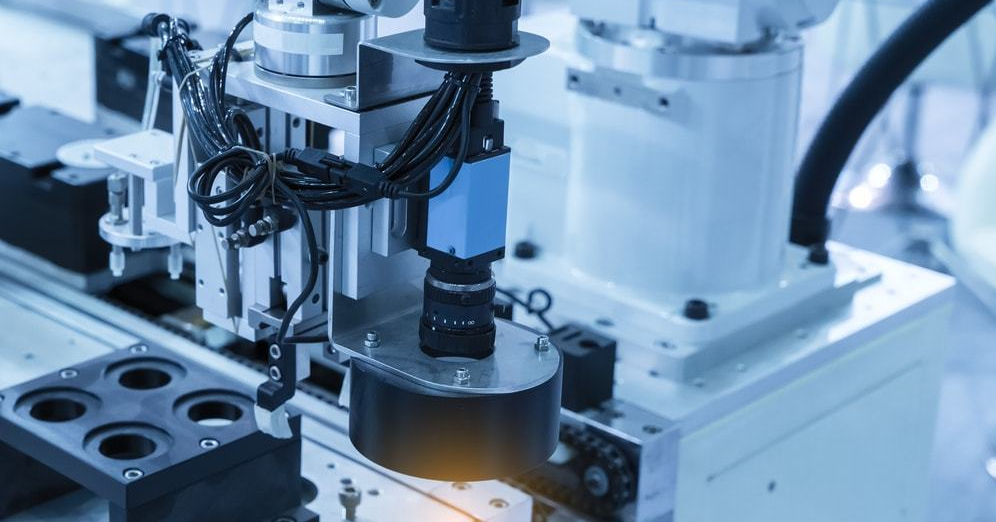

Vision Machine as one of the flagship products of Symkos, sucessfully built with hi-tech Camera inspection together with Vision Optics Lighting application. Our Machine Vision series solves applications, assembly and error detection, and character reading (OCR) at noise levels.

Combining power, accessibility and ease of use, SYMKOS Vision Machine can solve industrial inspection issue what was previously unsolvable, and ensures exellent performance at a better price.

Button

Slide title

Write your caption hereButton

Vision Machine as one of the flagship products of Symkos, sucessfully built with hi-tech Camera inspection together with Vision Optics Lighting application. Our Machine Vision series solves applications, assembly and error detection, and character reading (OCR) at noise levels.

Combining power, accessibility and ease of use, SYMKOS Vision Machine can solve industrial inspection issue what was previously unsolvable, and ensures exellent performance at a better price.

Inquiry

We will get back to you as soon as possible

Please try again later